What is Reverse Logistics?

Reverse logistics stands for all operations related to the reuse of products and materials. It is “the process of planning, implementing, and controlling the efficient, cost effective flow of raw materials, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal. More precisely, reverse logistics is the process of moving goods from their typical final destination for the purpose of capturing value, or proper disposal. Remanufacturing and refurbishing activities also may be included in the definition of reverse logistics.” The reverse logistics process includes the management and the sale of surplus as well as returned equipment and machines from the hardware leasing business. Normally, logistics deal with events that bring the product towards the customer. In the case of reverse logistics, the resource goes at least one step back in the supply chain. For instance, goods move from the customer to the distributor or to the manufacturer.

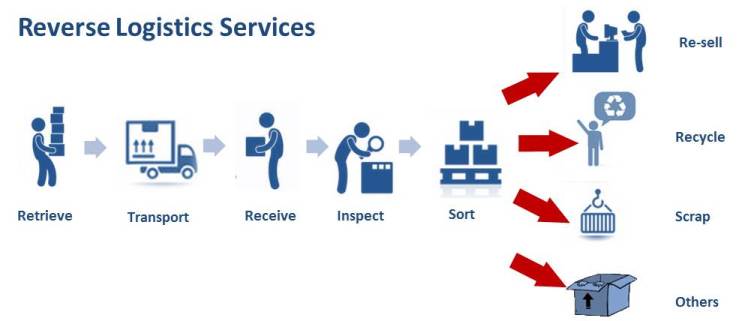

When a manufacturer’s product normally moves through the supply chain network, it is to reach the distributor or customer. Any process or management after the sale of the product involves reverse logistics. If the product is defective, the customer would return the product. The manufacturing firm would then have to organise shipping of the defective product, testing the product, dismantling, repairing, recycling or disposing the product. The product would travel in reverse through the supply chain network in order to retain any use from the defective product. The logistics for such matters is reverse logistics.

The Rise of Reverse Logistics in the E Commerce Freight Shipping World

Reverse logistics presents one of the biggest operational challenges in the world of eCommerce freight logistics due to the sheer volume and cost of processing returns. Effective reverse logistics is believed to result in direct benefits, including improved customer satisfaction, decreased resource investment levels, and reductions in storage and distribution costs. The amount of returned goods going backwards along the supply chain from the end point (customers) is usually much more than people normally think. As an example, the sheer volume of returns generated in many companies, ranged from 3% to as high as 50% of total shipments across all industries. Many other studies indicated the real costs of the returns take up roughly 3%-5% of total revenue. Surprisingly, for the traditional bricks-and-mortar retail operations, returns are 3 to 4 times more expensive than forward (outbound) shipments. In some industries such as book publishing, catalog retailing, and greeting card, over 20% of all products sold are eventually returned to the vendor. What’s more surprising is that some industries are estimated to have return rates in the range of 30 percent to 50 percent with other estimates are as high as 60 percent. Given the status quo of the reverse logistics, the neglect of the importance to the reverse part of the logistics flow opens an opportunity to create and manage customer relationships and build customer loyalty to the retailer.

What is Reverse Logistics Flow vs. Traditional Logistics Flow?

For reference, the traditional logistics flow is defined by the Council of Supply Chain Management Professionals glossary, as:

“The process of planning, implementing, and controlling the efficient, cost effective flow of raw materials, in-process inventory, finished goods and related information from the point of origin to the point of consumption for the purpose of conforming to customer requirements”

The same glossary defines reverse logistics as:

“The process of planning, implementing, and controlling the efficient, cost effective flow of raw materials, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal.”

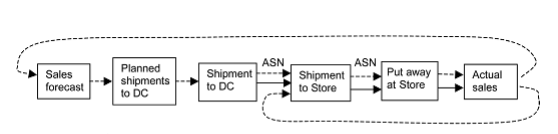

Reverse logistics is quite different from the traditional logistics, or forward logistics, activities. The below figure is a traditional logistics flow:

Sales forecast is used to project sale requirement, when certain amount product is required, they will be shipped to the DC (distribution center) and then shipped to the retail stores from DC. At every single level of the supply chain, ASNs (Advanced Shipping Notices) will be assisting the useful information as the products flow.

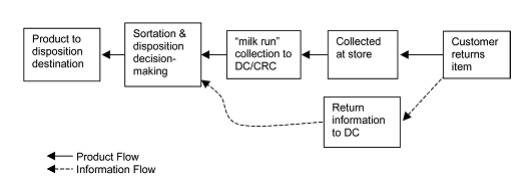

Reverse logistics flow, however, is a different story. Shippers generally do not initiate reverse logistics activity as a result of planning and decision making on the part of the firm, but in response to actions by consumers or downstream channel members. Here is the figure outlining what is reverse logistics flow:

When a return occurs, the returned product will be collected (in many different ways) and sent to the distribution center. At the same time the relevant information about the return item description, condition at return, customer information etc., will be transferred to the return processing center, but unfortunately, given the current state of the reverse logistics status quo, this information capture process rarely occurs, or occurs with less accuracy.